Office Hours

Mon - Fri: 8:00 am - 5:00 pm Closed on Weekends

Toll Free

1-800-850-3440

Locations

Youngstown, OH, Cleveland, OH & Pittsburgh, PA

Office Hours

Mon - Fri: 8:00 am - 5:00 pm Closed on Weekends

Toll Free

1-800-850-3440

Locations

Youngstown, OH, Cleveland, OH & Pittsburgh, PA

Dearing’s environmental division packages a wide range of standard and custom engineered trailer-based remediation systems.

Our most common systems are for dual phase extraction (DPE) which combines the remediation technologies of soil vapor extraction and ground water pump and treat for the in-situ remediation of volatile organics from soil and ground water.

Also known as multi-phase extraction, the vacuum system removes soil vapors and liquid pumps remove contaminated ground water. Vapors and ground water are separately treated and safely discharged back into the environment.

Dearing’s engineering department can also design site specific equipment. Previous designs have included diesel engines and generators for emergency environmental response, pump and treat trailers, soil vapor extraction trailers, custom wheel technology for injecting oxygen and other gases into returning groundwater, and highly efficient and effective oil water separators that greatly exceed the specifications of standard off the shelf systems based on water resident time.

We have over 60 years experience in equipment packaging. Please give us a call, and let us specify a system for you.

Advance oil/water separation from Industrial Service Technologies, Inc.

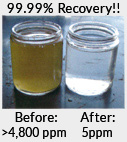

The OCX™ system employs the patented Hi-Flow™ Media cartridge to continuously separate entrained and emulsified oils from water with demonstrated removal efficiencies up to 99.99%. A standard 7″ X 20″ cartridge has processed more than 3 million gallons of oily water at a continuous flow rate of 7.5 gallons per minute, before cartridge replacement.

This photo shows typical results using two standard cartridges in series, at a flow rate of 7.5 gpm. System configurations can be varied to achieve desired recovery/removal target.

Multiple cartridge vessels are available to accommodate customer needs for high flow rate systems. Units from 3 to 475 gpm are available.

Fill out the Request a Quote form below, and a representative will be back to you shortly.

"*" indicates required fields

Toll Free: 1-800-850-3440

Email: info@dearingcomp.com

Toll Free: 1-800-850-3440

Email: info@dearingcomp.com

Toll Free: 1-800-850-3440

Email: info@dearingcomp.com

Toll Free: 1-800-850-3440

Email: info@dearingcomp.com

Toll Free: 1-800-850-3440

Email: info@dearingcomp.com

Toll Free: 1-800-850-3440

Email: info@dearingcomp.com

Copyright © Dearing Compressor & Pump Co. 2024 — All rights reserved. | Privacy Policy | Site Created By 898 Marketing

Mon - Fri: 8:00 am - 5:00 pm

Closed on Weekends

Toll Free

1-800-850-3440

Youngstown, OH, Cleveland OH, & Pittsburgh, OH