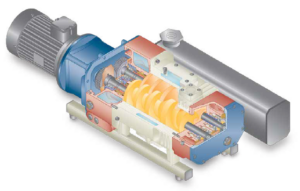

Screw vacuum pumps are positive displacement rotary pumps that are used to create a partial vacuum. They work by having two rotating screws that trap and move gas molecules through the pump, resulting in a reduction of pressure. This type of pump is often used in applications where a high degree of vacuum is needed.

At Dearing Compressor, we carry Gardner Denver S-Series screw vacuum pumps. Here’s an overview of how they function and what applications they’re best suited for.

What is a screw vacuum pump and how does it work?

A screw vacuum pump is a rotary sliding vane pump, consisting of two parallel screws with right-hand and left-hand threads. As these screws spin against each other, they create an airtight chamber that increases in volume as it moves towards the outlet.

A continuous decrease in pressure can be achieved by allowing material to enter at one side and leave through the other. This makes them suitable for applications relying on low-pressure higher-flow pumping. They’re also extremely efficient while dealing with small loads or low flow rates. A screw vacuum pump can work with materials ranging from dry solids to liquid phases, depending on the type of seal fitted along the vanes, making them hugely versatile across a range of industries.

What are the different types of screw vacuum pumps available on the market today?

There are a wide variety of screw vacuum pumps on the market that are available to meet any need. Dry running models are ideal for applications that require a greater amount of pressure but without contact between the moving parts; large scale models can be used in agricultural machinery and processing plants, while smaller models are suitable for laboratory and research use.

There are a wide variety of screw vacuum pumps on the market that are available to meet any need. Dry running models are ideal for applications that require a greater amount of pressure but without contact between the moving parts; large scale models can be used in agricultural machinery and processing plants, while smaller models are suitable for laboratory and research use.

The dry and contact-free operation of the Gardner Denver S-Series screw vacuum pumps requires no lubrication in the pumping chamber. This translates into major advantages: no process contamination and no pollution caused by the pump operation.

What are some of the most common industrial applications where screw vacuum pumps are used?

Screw vacuum pumps are widely used in industrial applications due to their highly efficient operation for cleaning, coating, drying and dust extraction processes. Common industrial settings where these pumps are employed include furniture manufacturing and other wood-working operations, electronic cleaning, chemical processing plants and the packaging industry.

Additionally, these pumps are used extensively in large-scale industrial furnaces as well as for off-gas discharge and venting. In these cases, the use of a reliable pump is essential for providing a sufficient evacuated space to efficiently facilitate cleaning without risking contamination from outside sources. With their robust construct and guaranteed performance capabilities, screw vacuum pumps have become an indispensable tool for a number of industrial processes.

Want to learn more?

Contact your Dearing Compressor sales rep and discuss how a Gardner Denver screw vacuum pump can work for your application.